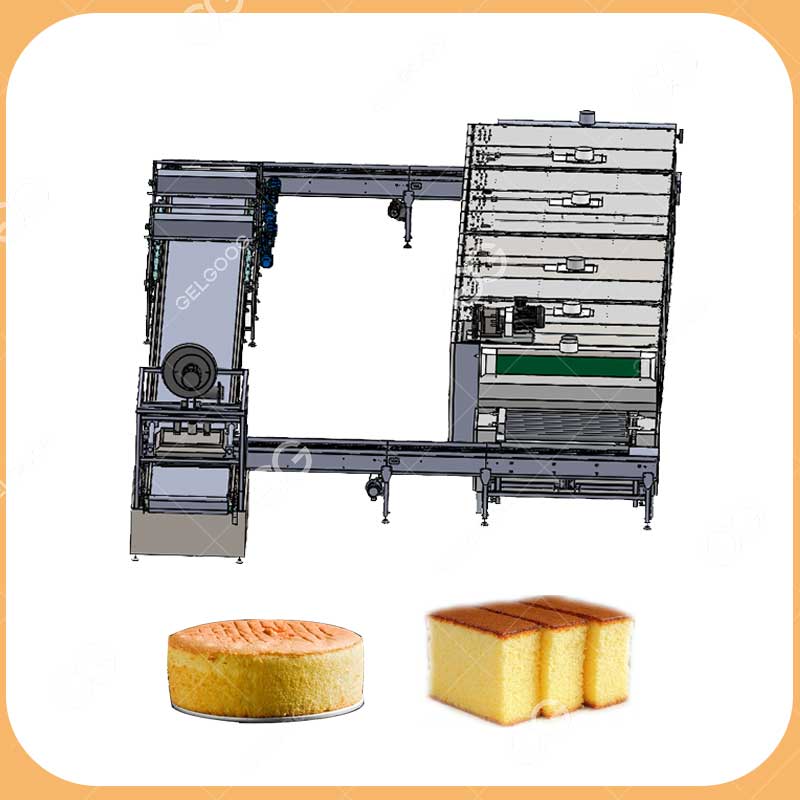

Our company produces a complete sponge cake production line with a wide output range, 100-1000 kg per hour. Not only that, the company also provides equipment for producing other kinds of cakes.

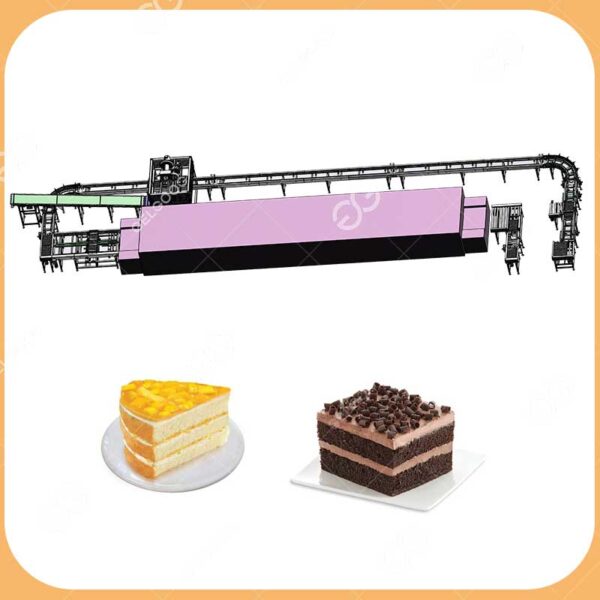

For example, the production of egg yolk pies, chiffon cakes, birthday cake embryos, cupcakes and other cakes of different specifications. Cakes of different weights and sizes can be made according to customer needs.

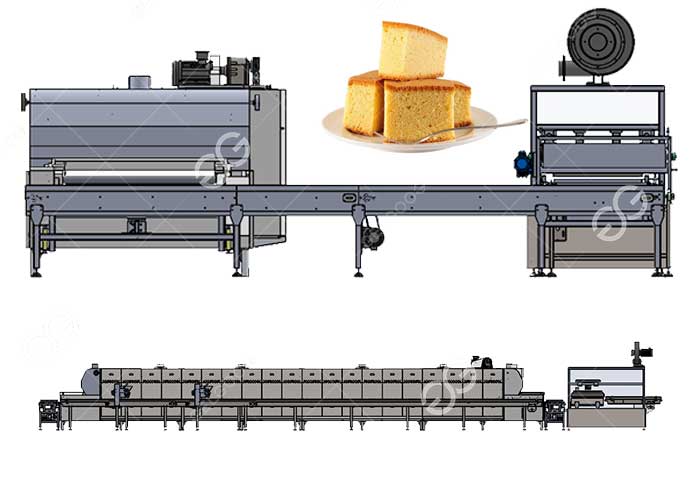

Process Flow of Sponge Cake Line

The main process is: raw material mixing→automatic feeding→mold spraying and oiling (or put paper tray)→batter injection and cake forming→sponge cake baking→cake cooling→(injection)→demoulding→sterilization→returning→winding up→cake packaging.

Description of Main Machines in Production Line

1.Batter Mixing Machine

This machine is a split type, and the mixer adopts a two-way arc-shaped stirring paddle, which makes the stirring speed faster and more uniform. The inflatable type adopts a horizontal enlarged mace-style high-speed hair head and staggered convex teeth to realize the aeration of the cutting slurry. It adopts touch screen operation interface and PLC program control, and can preset various stirring and sending programs, which is convenient for production operation. The density of the cake slurry sent by this machine is uniform and stable. The cake produced has a beautiful appearance and a soft and delicate taste. It is suitable for the production of sponge cakes, chiffon cakes and other products.

2.Oil Spraying Machine

The machine adopts German-style high-atomizing nozzles, the atomization effect is uniform, the amount of release oil is small, and the oil consumption of a single cake can be as low as 0.1 grams. Avoid the hardening of the bottom of the cake caused by too much base oil, and improve product quality. The equipment adopts electric eye tracking, PLC program control, touch screen operation interface, and convenient parameter setting.

3.Sponge Cakes Forming Machine

This machine adopts rolling injection type blanking, avoiding damage to the tissue of the aerated slurry during injection. A new compartmental hopper can be selected, which divides the hopper into equal compartments, each compartment can hold the same amount of material during blanking, and the weight of a single cake is stable during blanking, reducing blanking errors. It can also choose a single-row blanking format without separation, which is suitable for the production of products of various specifications.

4.Tunnel Cake Oven

The tunnel oven is suitable for baking cakes, bread, moon cakes, biscuits and other foods. The mechanical specifications include a variety of models, and the degree and width of the tunnel can be customized, which can be applied to different products and output requirements. The conveyor belt can choose chain plate type, mesh belt type, steel belt type, and choose different mesh belts according to the product.

5.Automatic Cake Demoulding Machine

Cake demoulding machine is a supporting machine for automatic cake production. The cake is transported to the designated position, and the cake is sucked out from the baking tray by the suction cup of the demoulding machine, and moved to the finished product conveyor belt, and the empty baking tray is transported to the return line for processing. Ready for the next cycle. According to different bakery products, choose the corresponding demoulding machine.

6.Sponge Cakes Packaging Machine

Pack cakes into bags according to the same weight to ensure food hygiene and quality, avoid contamination during transportation, and extend shelf life. Double frequency conversion control, bag length can be fixed and cut in one step, saving time and film. Positioning stop function, no sticking knife, no waste of film. All controls are realized by software, which is convenient for function adjustment and technology upgrade.

Video of Automatic Sponge Cake Production Line

Technical Parameter

|

Model

|

GG-Cake

|

|

Capacity

|

4807pcs/h(cake weight 78g/pc)

|

|

1718pcs/h(cake weight 32g/pc)

|

|

|

Size of baking plate

|

600*540mm

|

|

24pc cake/plate(cake weight 78g/pc)

|

|

|

48pc cake/plate(cake weight 32g)

|

|

|

Baking time

|

12 minutes

|

|

Baking temperature

|

185℃—210℃

|

|

Heating type

|

gas/electrical

|

Reviews

There are no reviews yet.