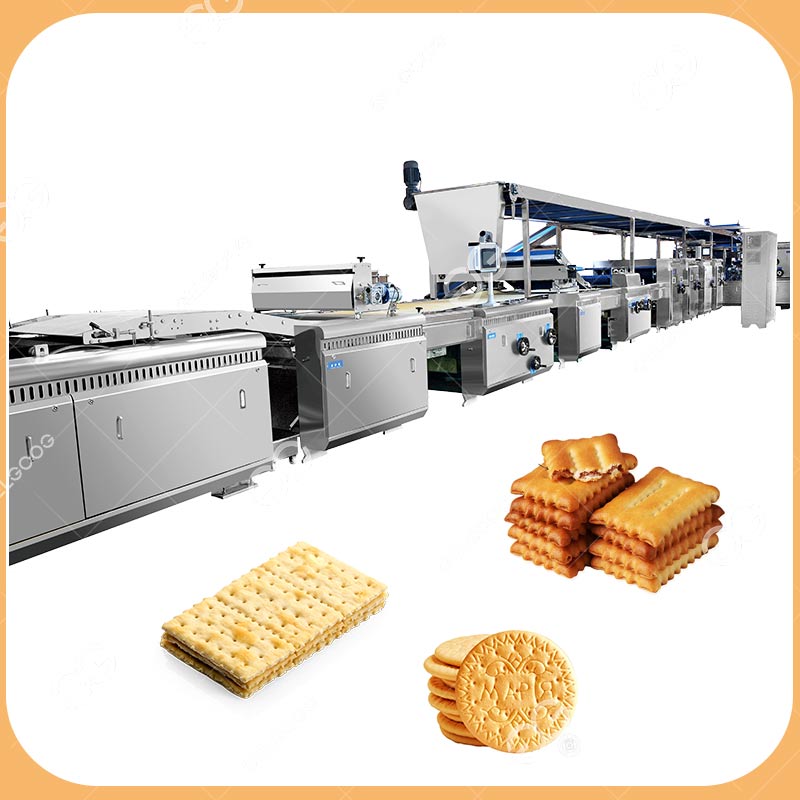

The hard biscuit production line is designed to produce hard biscuits on a large scale and improve the production capacity of biscuit manufacturers. It not only has professional machinery and technology, but also professional services.

The production line is usually automated and can produce a high volume of biscuits efficiently and consistently. We provide you with a complete biscuit solution, from raw materials to packaging.

Main Equipment of Hard Biscuit Production Line

- Dough Mixing Machine: The machine mixes the prepared ingredients (flour, sugar, oil, and other ingredients such as leavening agents and flavors) in proportion. Form a homogeneous dough after mixing.

- Dough Sheeter Machine: The dough is rolled through multiple passes to flatten it into biscuit dough sheets of a specific thickness. Usually the thickness of the dough sheet can be rolled to 0.8 mm, and the thinnest can reach 0.6 mm.

- Hard Biscuit Forming Machine: The dough sheet is rolled into a uniform biscuit embryo by the principle of roller cutting, and the excess dough between the cut biscuits is usually recycled to avoid waste.

- Biscuit Baking Oven: The tough biscuits enter the large tunnel oven through the conveyor belt, and the biscuits are baked into a uniform texture through four stages of expansion, shaping, dehydration, and coloring.

- Cooling and sterilization line: The baked biscuits pass through the cooling conveyor belt to reduce the temperature and avoid moisture retention, which will affect its crispness and facilitate the next step of packaging.

- Packaging Machine: After the biscuits are cooled and sterilized, in order to extend the shelf life, the packaging machine packs the biscuits into boxes, bags or other containers for distribution and sale.

Video of Hard Biscuit Production Line

Multifunction of Hard Biscuit Line

This production line is multi-purpose, if you want to save costs, a set of equipment can also make different styles of biscuits. The following are examples of common hard biscuit forming molds.

Product Parameters:

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method | Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Reviews

There are no reviews yet.