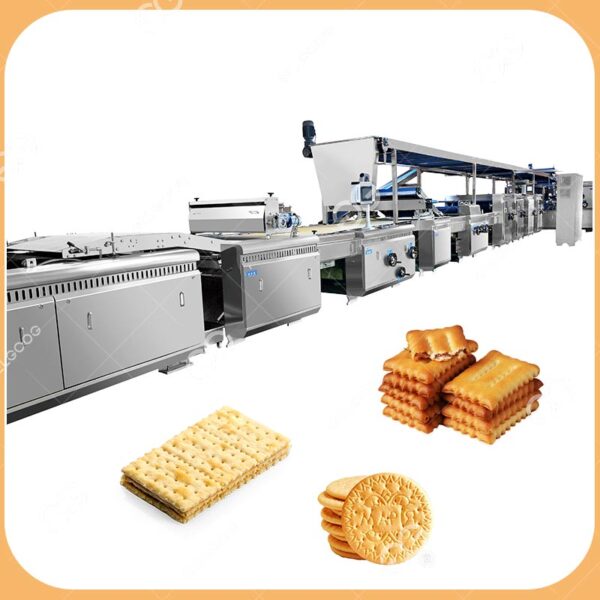

The cracker production line is a high-quality, large-scale system engineered to streamline the production of crackers. The machine applies advanced technology to produce high-quality crackers and biscuits.

Crackers are a beloved snack enjoyed by people of all ages and backgrounds. Whether paired with cheese, dipped in hummus, or eaten straight from the box, these crispy delights have long been a staple in the world of snacks. Enter the Industrial cracker machine, a sophisticated system that has revolutionized the way these iconic snacks are manufactured.

Key Components of Industrial Cracker Production Line

♦Dough Mixing: The production process starts with the careful mixing of ingredients to create the cracker dough. Modern production lines use computer-controlled mixers to ensure consistent dough quality and precise ingredient ratios.

♦Sheeting and Rolling: After dough preparation, it is rolled and flattened into thin sheets. These sheets are then rolled through precision rollers to achieve the desired thickness, ensuring uniformity across all crackers.

♦Cutting and Molding: Specialized cutting and molding equipment are used to create various cracker shapes and sizes. From traditional square and rectangular crackers to intricately designed patterns, the production line can be customized to meet market demands.

♦Baking Ovens: The crackers are then baked in high-capacity ovens that provide even and consistent heat distribution. These tunnel ovens are designed to maximize efficiency while maintaining precise temperature and humidity levels for optimal cracker quality.

♦Flavoring and Seasoning: A key feature of this production line is the ability to add flavors and seasonings to the crackers. Whether it’s a sprinkle of sugar powder, sea salt, a dusting of herbs, or a savory cheese coating, customization options are virtually limitless.

♦Quality Control and Packaging: Advanced sensors and quality control measures are integrated into the production line to ensure that only high-quality crackers reach the packaging stage. After passing inspection, the crackers are efficiently packed into boxes or other containers, ready for distribution.

Video of Cracker Production Line

Advantages of Cracker Processing Line

- Consistency: Precise control over every aspect of production ensures consistent quality and taste in every cracker.

- Mass Production: The automated nature of this production line allows for large-scale production, meeting the high demand for crackers in the market.

- Customization: Manufacturers can easily adapt the production line to create a wide range of cracker varieties, catering to diverse consumer preferences.

- Efficiency: Reduced labor costs, decreased product waste, and energy-efficient design make the industrial cracker production line a cost-effective solution for cracker production.

- Hygiene and Safety: The machinery is designed with strict food safety and hygiene standards in mind, ensuring the safety of the end product.

Product Parameters:

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method | Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Reviews

There are no reviews yet.