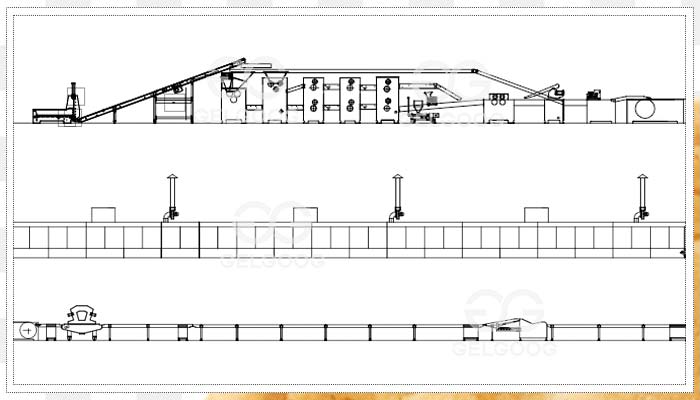

This complete marie biscuit production line has the characteristics of stable operation, wide application and high production efficiency. It is an ideal equipment for producing marie biscuits.

The production line is made of food-grade stainless steel, and the equipment is durable and easy to clean. Compared with similar products, it has more advantages, good quality and affordable price.

Advantages of Marie Biscuit Production Line

- Diversified production: One production line can produce a variety of products, including hard biscuits and soft biscuits, to meet the needs of different consumers. For biscuit manufacturers, this can reduce investment costs and improve production efficiency.

- New flavor: The unique double-layer sandwich biscuit can be well combined with local flavor food and bring a new experience to consumers. For biscuit manufacturers, this can open up new markets and enhance competitiveness.

- High quality: Using first-line brand production processes and equipment, product quality can be guaranteed. For biscuit manufacturers, this can enhance their brand image and win the trust of consumers.

- Stable operation: The automatic marie biscuit production line operates stably, and the production qualification rate can reach more than 95%. For biscuit manufacturers, this can reduce production costs and improve production efficiency.

- All-round guidance: It has the planning ability of the complete marie biscuit line solution and can provide all-round production guidance to help customers improve production efficiency and product quality. For biscuit manufacturers, this can reduce production costs and improve production efficiency.

- Renovation and upgrade: Existing production lines can be renovated and upgraded to meet customer needs. For biscuit manufacturers, this can improve production efficiency and product quality.

The Company can Provide You with the Following Services:

- Process design: Provide biscuit process solutions suitable for production according to your needs.

- Equipment selection: According to the process plan, select appropriate equipment and configure the marie biscuit machine.

- Installation and debugging: Responsible for the installation and debugging of equipment to ensure normal operation of the equipment.

- Production training: Provide production training to customers to help them become familiar with production processes and equipment operations.

- After-sales service: Provide after-sales service to ensure the normal operation of the marie biscuit processing line.

Maintenance of Marie Biscuit Production Line

Daily Maintenance

- At the end of each day of biscuit production, the equipment should be cleaned to ensure the normal operation of the equipment. When cleaning, use a special cleaning agent and be careful not to damage the surface of the equipment.

- The production line should be inspected once a week. When inspecting, focus on the equipment’s transmission components, electrical components, and lubrication components.

Regular Maintenance

- The machine should be overhauled once every six months. During overhaul, worn parts should be replaced and necessary adjustments made.

- The biscuit machine should be maintained once a year. When maintaining, clean the internal dirt of the equipment and check the various components of the equipment to extend the service life of the equipment.

Product Parameters:

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method | Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Reviews

There are no reviews yet.