The custard tart machine is mainly composed of the host, the control panel, the push rod, the turntable, the upper and lower molds, the cup drop device, the conveyor belt and so on. It is suitable for making multi-style custard tarts to meet the needs.

The production process of custard tart: quantitative dough cutting—dough conveying—hot pressing forming—tart shells conveying—arranging the tart shells

Features of Tart Shell Press Machine

1. The parts in contact with food are made of 304 stainless steel, which is stable, reliable and hygienic in production.

2. It is suitable for large and medium-sized bakery manufacturers to process egg tarts with different characteristics.

3. Using brand components, the unit is equipped with a complete set of Japanese structure knives, German optoelectronics, drive motors, frequency converters, Italian conveyor belts, etc.

4. The whole set of egg tart equipment has low energy consumption and is easy to operate, which can be operated by one person.

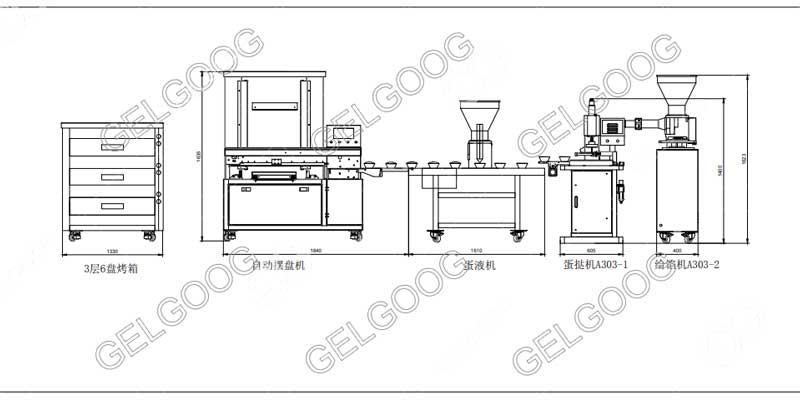

5. It can be matched with other related equipment to form an automatic egg tart processing line.

Testing Video of Custard Tart Machine

Advantages of Industrial Tart Press Machine

1. Equipped with a discharging system, the dough can be cut quantitatively, and the size of the formed tart crust is consistent.

2. Tart shell press machine uses imitation handmade technology, the appearance is flat and smooth, to ensure that the baking process of the product is not affected.

3. The upper mold has double anti-sticking settings: ①The surface is coated with Teflon material to prevent sticking; ②The temperature of the built-in heating device is controllable to prevent sticking.

4. This egg custard tart machine has a wide application range, can produce egg tart skins of different sizes and styles.

5. The shape of the abrasive tool can be customized according to customer needs, and the exquisite design is easy to disassemble, install and clean.

Operating Procedures of Tart Pressing Machine

A. Connect the power supply–connect the air pipe–turn on the power (emergency stop) button–semi-automatically debug the tart shells product–select the automatic mode–press the start button–put the aluminum cup and filling into the mold hole Inside–automatic forming–discharging–complete

B. Mold replacement steps: Turn off the power–Loosen the upper mold screws and remove the power supply of the electric heating ring–Loosen the three screws on the disc to remove it–Install a new mold–Install the disc after installation upper die–test the thickness of the custard tart shells in a semi-automatic state.

Technical Parameter

| Model | GGA303-1 |

| Capacity | 1500-1800PCS/H |

| Voltage | 220V,50hz |

| Diameter of Tart | 40-90mm |

| Size | 840*800*1300mm |

| Weight | 130kg |

Reviews

There are no reviews yet.