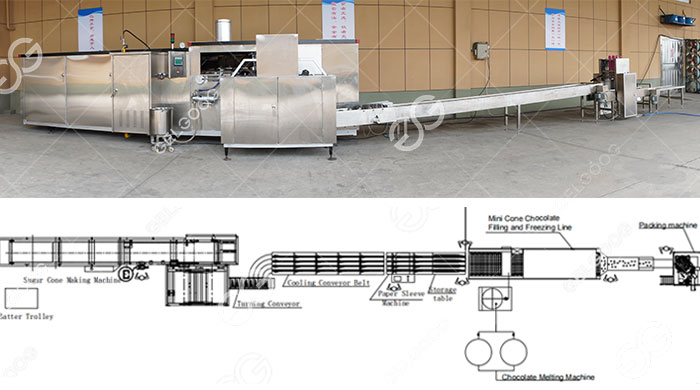

This waffle cone production line is specially used to produce this muddy bites waffle cones, with large output and good quality. This snack is a popular choice for serving ice cream and other frozen treats.

Process of Muddy Bites Waffle Cones

Prepare the required formula raw materials→ Stir the slurry→ Fill the slurry→ Sheet baking→ Picking→ Cone rolling;

Chocolate melting pot→ Fill the chocolate sauce→ Mini chocolate cones packing.

Features of Automatic Waffle Cone Production Line

- The machine made with food grade high quality stainless steel, the muddy bites waffle cone snack also health and safety.

- This production line can produce 1500-7500pcs waffle cones per hour, with large output, and the quality of the muddy bites waffle cone is also consistent.

- This machine is multifunctional, and can produce different sizes of sugar cones, only a small amount of labor is required in the whole process.

- The muddy bites waffle cone production line’s baking plates are made of nodular cast iron material, which is more durable and heats up quickly.

- The conveyor belt is aluminium alloy material, it is more strong and sturdy, and has a long service life.

Steps of Making Waffle Cones

- Ingredients Preparation: The basic ingredients for waffle cones include flour, sugar, eggs, butter or vegetable oil, and flavorings like vanilla. Mix these ingredients into a batter. You can also make the batter according to your own recipe.

- Heating the Batter: Fill the smooth batter on the baking plates, then heat to a specific temperature to cook the batter and create a biscuit sheet.

- Rolling Cones: Place the biscuit sheets in the rolling machine, then roll these sheets into ice cream cones. These cones have a consistent size with very little breakage.

- Melted Chocolate: Heat the chocolate in a bucket to make the chocolate sauce, which is then filled into small waffle cones.

- Packaging: Once the waffle cones filled with chocolate are completely cooled and set, they are ready for packaging. They can be packaged in bulk for distribution to ice cream shops or packaged individually for retail sales.

Video of Muddy Bites Waffle Cone Line

Product Parameters:

| Model | Baking plate size(mm) | Voltage | Power | Capacity | Cone length | Size | Weight |

| GG-DCL35×2-18 | 300×320 | 380v 50hz 3phase | 3kw | 1500-2500pcs/h | ≦125mm | 6*0.8*1.85m | 6T |

| GG-DCL37×2-18 | 300×320 | 3kw | 3500-4000pcs/h | ≦125mm | 7*0.8*1.85m | 6T | |

| GG-DCL45×2-18 | 300×320 | 3kw | 4000-4500pcs/h | ≦125mm | 8*0.8*1.85m | 6T | |

| GG-DCL55×2-18 | 300×320 | 3kw | 4500-5500pcs/h | ≦125mm | 9*0.8*1.85m | 7T | |

| GG-DCL65×2-20 | 300×320 | 3kw | 6000-6500pcs/h | ≦125mm | 11*0.8*1.85m | 7T | |

| GG-DCL75×2-22 | 300×320 | 3kw | 6500-7500pcs/h | ≦125mm | 11*1.9*1.85m | 8T |

bakery –

seo sei seo seo seo