The fully automatic ice cream cone making machine is a piece of specialized equipment for processing a large capacity of ice cream cones. There is a production range of 1500-7500 pcs/h, and can be cones in different sizes to meet different market demands.

These ice cream cone machines from GELGOOG company simplify the production of ice cream cones and the whole process is automatic. Suitable for use in ice cream factories, cone factories, food factories, etc.

The automatic ice cream cone machine is a robust industrial-grade appliance that can produce a high volume of ice cream cones with minimal manual intervention. It is an ideal choice for businesses that need to meet high demand while maintaining product quality and consistency.

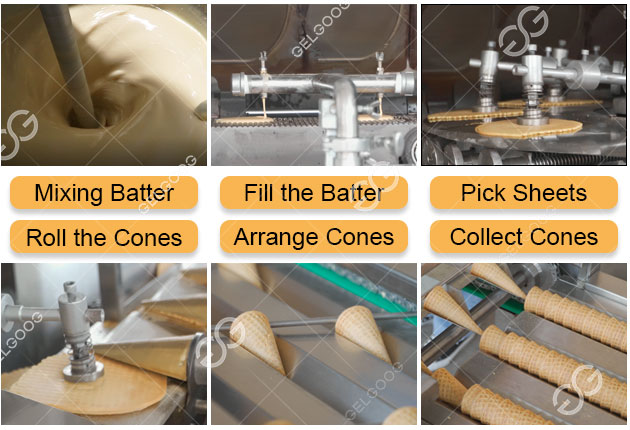

What is the Process of Making Ice Cream Cone?

- Prepare the Batter: In a mixing machine, combine flour, sugar, salt, eggs, and other ingredients. Then blend these ingredients until smooth, lump-free batter.

- Fill the Batter: Pour the smooth batter into the storage bucket, and then lift the batter to the grouting port by the pump and falls onto the baking plates. The amount of grouting can be adjusted according to actual requirements.

- Baking the Cones: The baking host is equipped with a PLC display, which can set the required temperature, baking time, etc. on the display. After baking, the biscuit slices are uniform in color and bright in color.

- Roll the Cones: A mechanism places the crispy biscuit sheet under the roll head and rolls it into a cone shape. You can adjust two places to realize the function of making ice cream cones of other sizes.

- Conveyor and Arrange Cones: These ice cream cones fall from the rolling machine onto a conveyor belt. Complete the process of arranging, set paper trays, stacking, etc.

Features of Automatic Ice Cream Cone Machine

- High Production Capacity: It has a high speed production, per hour can produce 7500 pieces of ice cream cones. The specific capacity varies from model to model, and they are usually designed according to your needs.

- Fully Automatic Operation: The key feature of this ice cream cone machine is its full automation. It can handle the entire cone making process, from mixing the batter to baking and shaping the cones. This reduces the need for manual labor and ensures consistent product quality.

- User Friendly Control Panel: With an intuitive control panel that allows operators to adjust settings such as temperature, baking time, and cone size. This flexibility enables customization to meet specific product requirements.

- Quality and Safety: The ice cream cone making machine is built with food-grade materials and are designed to meet strict hygiene and safety standards. They often come with safety features to protect operators during operation.

- Versatility: Some models may offer the option to produce different types of cones, such as waffle cones or sugar cones, by simply adjusting settings.

- Easy Maintenance: Manufacturers often design these machines for easy cleaning and maintenance to minimize downtime and ensure longevity.

Video of Ice Cream Cone Making Machine

Product Parameters:

| Model | Baking plate size(mm) | Voltage | Power | Capacity | Cone length | Size | Weight |

| GG-DCL35×2-18 | 300×320 | 380v 50hz 3phase | 3kw | 1500-2500pcs/h | ≦125mm | 6*0.8*1.85m | 6T |

| GG-DCL37×2-18 | 300×320 | 3kw | 3500-4000pcs/h | ≦125mm | 7*0.8*1.85m | 6T | |

| GG-DCL45×2-18 | 300×320 | 3kw | 4000-4500pcs/h | ≦125mm | 8*0.8*1.85m | 6T | |

| GG-DCL55×2-18 | 300×320 | 3kw | 4500-5500pcs/h | ≦125mm | 9*0.8*1.85m | 7T | |

| GG-DCL65×2-20 | 300×320 | 3kw | 6000-6500pcs/h | ≦125mm | 11*0.8*1.85m | 7T | |

| GG-DCL75×2-22 | 300×320 | 3kw | 6500-7500pcs/h | ≦125mm | 11*1.9*1.85m | 8T |

Reviews

There are no reviews yet.