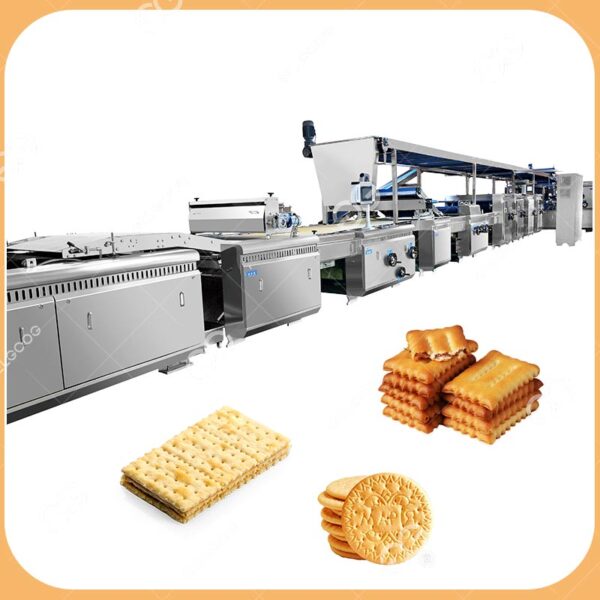

Biscuit manufacturing machine provides advanced equipment to produce various biscuits in the field of modern food processing. It simplifies the production process and makes biscuit processing more intelligent.

Features of Automatic Biscuit Plant

- Precision Engineering: The heart of the machine in its precision engineering. Each component is meticulously designed to ensure uniformity in size, shape, and texture of the biscuits. This precision not only enhances the visual appeal of the end product but also contributes to the consistent taste that consumers have come to expect.

- Versatility: This machine can produce various types of biscuits, not only sandwich biscuits, chocolate biscuits, bear biscuits, but also crackers. And it can also be customized just for you. Biscuit manufacturers can meet the changing needs of the market without having to modify or repurchase equipment.

- High Production Capacity: The production line has different production capacities, from 100 to 1200 kg per hour. Increased the number of cookies produced in a given time. Not only does this increase production, it also allows manufacturers to meet growing market demand efficiently.

- Energy Efficiency: In pursuit of sustainable development, the biscuit factory optimizes resource utilization, minimizing the energy consumption of its bisacuit plant while maximizing its output.

Advantages of Biscuit Manufacturing Machine

- Increased Productivity: With the ability to operate continuously and consistently, the automatic biscuit plant vastly improves overall productivity. Human errors and fatigue, common in traditional production methods, are mitigated, ensuring a streamlined and efficient manufacturing process.

- Quality Assurance: The precision and automation of the machine contribute to unparalleled quality assurance. Each biscuit that rolls off the production line meets stringent quality standards, instilling confidence in both manufacturers and consumers alike. Consistency in taste and appearance becomes a hallmark of the brand.

- Cost Efficiency: While the initial investment in a biscuit manufacturing plant may seem substantial, the long-term cost efficiency cannot be overstated. The reduction in labor costs, coupled with increased production capacity and energy efficiency, results in a significant return on investment over time.

Video of Automatic Biscuit Manufacturing Machine

Product Parameters:

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method | Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Reviews

There are no reviews yet.