The swiss roll production line is a new type of cake production line developed by our company, which is automatically completed from stirring and forming, baking, rolling, cutting, cooling and sterilization to packaging.

The machine adopts frequency conversion, light, electricity and gas automatic control, making the entire swiss roll cake production operation more convenient and labor-saving.

Features of Swiss Roll Cake Production Line

- Equipped with two sets of forming mechanisms, it can produce Swiss rolls and sandwich cakes; equipped with two sets of cream coating mechanisms, it can quickly change the taste of products.

- The steel belt oven uses well-known brand steel belts. The oven length is 30 meters. Calculated according to the baking time of 7 minutes, the output can reach 600 kilograms per hour.

- This swiss roll processing line can choose electric heating and gas heating ovens, which can be applied to different energy conditions in various places, which is convenient for customers to control product costs.

- The main mechanism and materials are made of 304 stainless steel, aluminum alloy, high-quality nylon and other food-grade materials.

- The machine can make cakes without molds, as long as the gap between the cutters is replaced and the speed of the cross cutters is adjusted, so that the size of the cakes can be large or small.

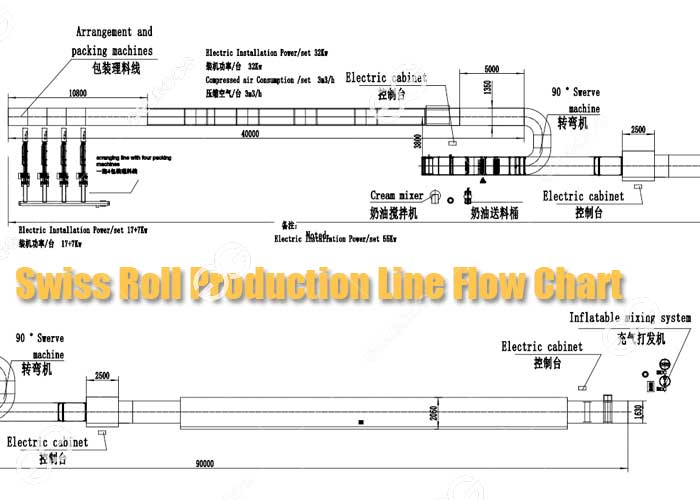

Swiss Roll Production Line Flow Chart

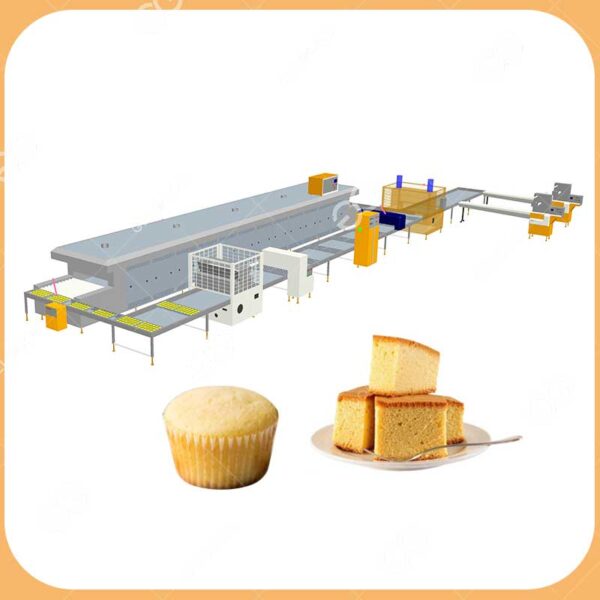

Application of Automatic Swiss Roll Machine

This production line can produce Swiss rolls in different sizes and flavors, with the addition of cream, jam, chopped nuts, icing, chocolate and more. Swiss roll is also known as jelly roll (United States), roll cake, cream roll, roulade or Swiss log.

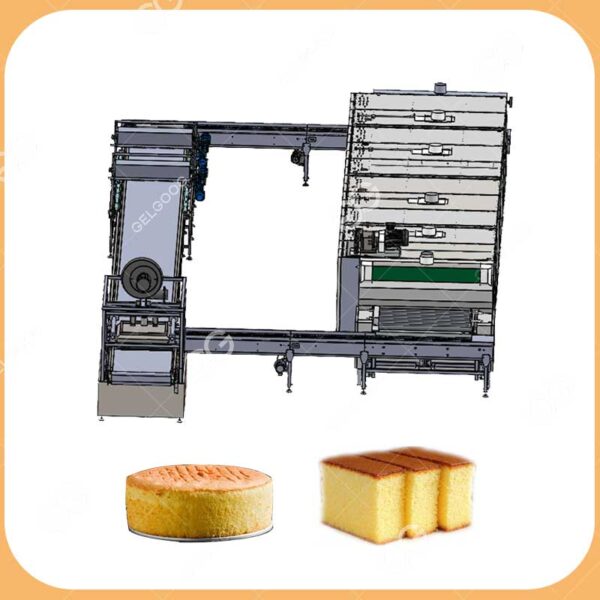

Main Machines of Swiss Roll Cake Line

- Industrial Mixer: This machine specially designed for preparing cake batter, with large capacity and can process hundreds of kilograms per hour.

- Cake Filling Machine: Used to fill cake batter into the tray, the amount and speed of filling can be adjusted.

- Tunnel Oven: The length of the oven can be customized as required to meet different production capacities. Control the temperature and speed to bake Swiss roll cake.

- Cooling Sterilization Line: After the cake is baked, it is cooled by a conveyor belt to reduce the temperature of the cake to a packaging temperature. And enter the sterilization room to eliminate bacteria.

Advantages of Our Factory

1. A set of cake production equipment independently developed by combining domestic and foreign consumer market demand. Meet the needs of users to the greatest extent.

2. As the manufacturer of swiss roll production line, our factory has produced several production lines and provided users with professional cake solutions.

3. We support factory inspection, factory visit, test machine, after-sales installation and maintenance, spare parts supply service, etc.

Technical Parameter

|

Model

|

GG-Cake

|

|

Capacity

|

4807pcs/h(cake weight 78g/pc)

|

|

1718pcs/h(cake weight 32g/pc)

|

|

|

Size of baking plate

|

600*540mm

|

|

24pc cake/plate(cake weight 78g/pc)

|

|

|

48pc cake/plate(cake weight 32g)

|

|

|

Baking time

|

12 minutes

|

|

Baking temperature

|

185℃—210℃

|

|

Heating type

|

gas/electrical

|

Reviews

There are no reviews yet.