The muffin cake production line is suitable for making different flavors of muffine cakes, such as chocolate muffins, blueberry muffin, etc. High degree of automation and efficient production process.

As a professional cake production line manufacturer, our main equipment has sponge cake production line, cupcake production line, swiss roll production line, and so on. We provide a variety of high-quality bakery equipment for the majority of food processing factories to meet the various needs.

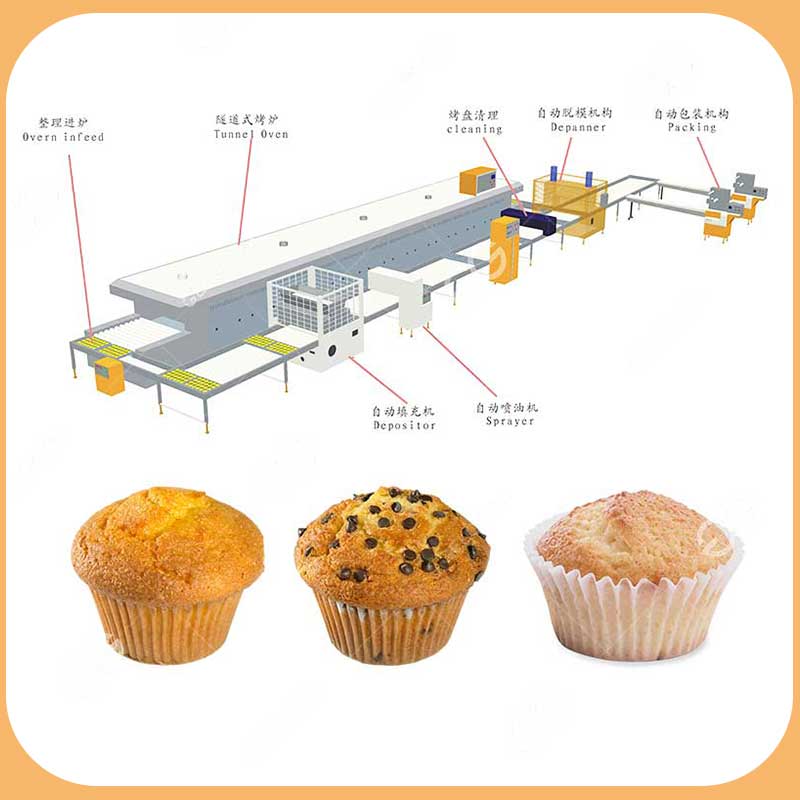

Components of Industrial Muffin Cake Production Line

Beating machine–Paper tray machine– Cake batter filling machine– Oil sprayer– Baking in the oven– Cooling out of the oven– Stuffing machine– De-moulding machine– Winding machine– Cooling and sterilizing belt– Packaging Machine.

- Mixing Machine: Capable of blending ingredients uniformly and efficiently. It typically has a high-speed mixer for quick mixing and a variable speed control for precision.

- Depositor Machine: Designed for precise and consistent batter dispensing. It can handle a variety of batter viscosities and is equipped with a control system for accurate volume measurement.

- Muffin Baking Plate: Constructed with heat-resistant materials, this plate ensures uniform heat distribution across the muffin batter, leading to evenly baked muffins. Its non-stick surface is designed for easy release of the finished product, enhancing efficiency in high-volume production.

- Baking Oven: Features precise temperature control and uniform heat distribution for consistent baking results. It may also have adjustable baking times and fan-assisted convection for even baking.

- Cooling Conveyor: Operates at a controlled speed to provide sufficient cooling time without over-drying the muffins. It may include multiple levels or zones for efficient use of space.

- Mold Release System: Efficiently releases the muffins from the molds, which can be a simple mechanical action or a more complex automated system depending on the production scale.

- Packaging Machine: Automated to handle high-speed packaging, with options for different packaging materials and styles, ensuring product protection and presentation.

- Sanitizing Equipment: Capable of thorough cleaning and sanitizing of production line components, often using high-pressure water or chemical solutions to ensure cleanliness and food safety standards are met.

Advantages of Muffin Production Line

- Exquisite materials: the whole line including the outside of the oven is made of stainless steel, and the electronic components are made of well-known brands at home and abroad to ensure lower equipment failure rate and higher stability. Thickness up to 300mm, good heat preservation effect, can ensure the surface temperature and better baking effect.

- High degree of automation: The baking oven adopts PLC touch screen control system to prevent misoperation control, automatic safety detection and processing, Chinese and English alarm display and advanced PID temperature control system.

- One machine for multiple purposes: This muffin production line can produce core-injected egg yolk pie cakes, cupcakes and sliced cakes. According to the shape of the mold plate, it can produce different shapes of colored cakes.

- High safety: The oven adopts a gas high-voltage protection switch unit, which is interlocked for protection, and the high-voltage igniter has a single fire extinguishing alarm independent processing system, which cooperates with the PLC control system to realize the safety monitoring of the combustion of the whole machine. Cut off the gas within 1 second to effectively ensure the safety of equipment operation and use.

- Intelligent stand-alone equipment: This machine can automatically fill the whole row of cakes with core. If it senses that a cake is not on the production line, the core-filling needle will not fill the core, so as to avoid filling on the conveyor belt. While greatly improving the production efficiency, it avoids the waste of materials and the cleaning process.

Working Video of Muffin Cake Production Line

Technical Parameter

|

Model

|

GG-Cake

|

|

Capacity

|

4807pcs/h(cake weight 78g/pc)

|

|

1718pcs/h(cake weight 32g/pc)

|

|

|

Size of baking plate

|

600*540mm

|

|

24pc cake/plate(cake weight 78g/pc)

|

|

|

48pc cake/plate(cake weight 32g)

|

|

|

Baking time

|

12 minutes

|

|

Baking temperature

|

185℃—210℃

|

|

Heating type

|

gas/electrical

|

Reviews

There are no reviews yet.