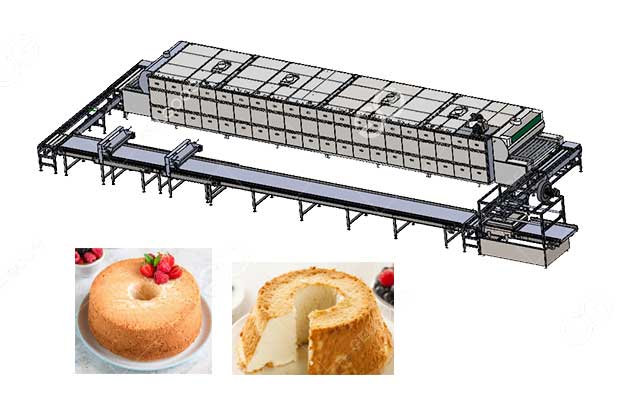

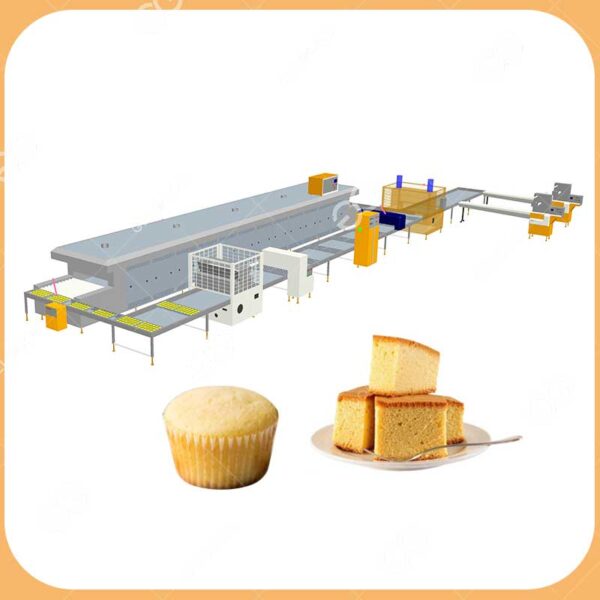

The angel food cake production line can produce angel food cakes with high efficiency, and can process hundreds or even thousands of kilograms per hour on average. The entire process is highly automated, effectively reducing labor expenses.

Angel cake attracts food lovers with its light texture and slightly sweet taste. This heavenly product is due not only to the delicate balance of ingredients, but also to the precision and innovation of the cake line.

1. Mixing and Preparation

The signature texture and flavor stem from meticulous preparation. The angel food cake production line begins with a precisely calculated mix of ingredients—flour, sugar, and whipped egg whites—to create the batter. The blending process requires finesse to ensure the batter’s lightness and uniform consistency, setting the stage for the cake’s characteristic airy crumb.

2. Baking Equipment

The batter moves onto specialized baking pans designed specifically for Angel Food Cake. The unique shape of these pans, with a hollow center tube, facilitates even heat distribution, crucial for achieving the cake’s distinct rise and texture. Advanced ovens, equipped with precise temperature controls, bake the cakes to perfection, resulting in their coveted golden hue and fluffy interior.

3. Precision in Cooling and Unmolding

Once baked, the cakes undergo a meticulous cooling process. Cooling racks, integrated into the angel cake production line, allow for adequate airflow around the angel food cakes, preventing them from collapsing while maintaining their feathery lightness. Unmolding the delicate cakes requires finesse and precision, ensuring their flawless release from the pans without compromising their structure.

4. Packaging and Preservation

Packaging plays a pivotal role in preserving Angel Food Cakes’ delicate texture and taste. Automated systems carefully seal the cakes in airtight packaging to maintain their freshness, protecting them from moisture and air. These packaging materials are designed to prolong shelf life without compromising the cakes’ heavenly attributes.

Angel food cake production line showcase adaptability to cater to evolving consumer preferences. Whether it’s introducing variations like gluten-free or organic options, these lines swiftly adapt to new recipes and techniques. Innovation drives the incorporation of modern technology, enhancing efficiency without compromising the cake’s traditional charm.

Stringent quality control measures are integrated into the production line to ensure consistency in taste, texture, and appearance. Automated inspection systems detect imperfections, guaranteeing that only flawless Angel Food Cakes reach consumers, maintaining the brand’s reputation for excellence.

Working Video of Angel Cake Production Line

Technical Parameter

|

Model

|

GG-Cake

|

|

Capacity

|

4807pcs/h(cake weight 78g/pc)

|

|

1718pcs/h(cake weight 32g/pc)

|

|

|

Size of baking plate

|

600*540mm

|

|

24pc cake/plate(cake weight 78g/pc)

|

|

|

48pc cake/plate(cake weight 32g)

|

|

|

Baking time

|

12 minutes

|

|

Baking temperature

|

185℃—210℃

|

|

Heating type

|

gas/electrical

|

Reviews

There are no reviews yet.