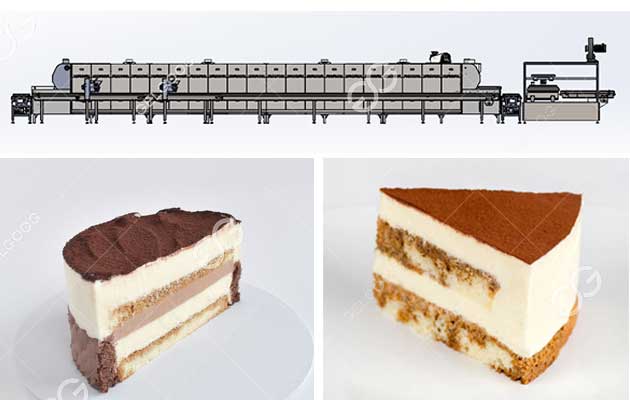

The tiramisu production line we produce is designed to simplify the production process and produce tiramisu cakes efficiently. The supporting packaging system packages the cakes for distribution to various locations.

The tiramisu cakes produced by the equipment always maintain uniform high quality. From beating, filling, to baking, cooling, demoulding and packaging, a series of operations are completed automatically.

Features of Tiramisu Production Line

- Automated production, precise control of various indicators in production. Not only has efficiency been greatly improved, labor costs have also been reduced, and manual intervention and human errors have been minimized.

- Use a high-performance tunnel oven or rotary oven for better cake baking. The oven adopts precise temperature control, and the surface of the product is evenly colored, bright in color, and fluffy and soft in taste.

- Our automated tiramisu cake lines ensure consistent product size, texture and color. Produce high-quality tiramisu for your company, win the favor of consumers, and create a good reputation.

- The main processes include automatic oil spraying, grouting, core injection, demoulding, automatic transportation, sterilization, packaging, etc.

- Adopt high-precision temperature control and digital temperature display. Constant temperature control, the temperature is more stable, the combustion is sufficient, energy saving, environmental protection and pollution-free.

Video of Tiramisu Cake Production Line

Advantages of Tiramisu Production Line

- Productivity: Automated processes minimize labor costs and maximize output.

- Superior product: Equipment production ensures that each tiramisu is consistent in size, shape and texture.

- Reduce waste: Precise control minimizes unnecessary waste during cake production.

- Extended Shelf Life: Vacuum sealing extends the shelf life of your tiramisu, reducing spoilage and maximizing profits.

- Increased product appeal: Automated packaging ensures that the tiramisu comes in elegant and protective packaging.

Technical Parameter

|

Model

|

GG-Cake

|

|

Capacity

|

4807pcs/h(cake weight 78g/pc)

|

|

1718pcs/h(cake weight 32g/pc)

|

|

|

Size of baking plate

|

600*540mm

|

|

24pc cake/plate(cake weight 78g/pc)

|

|

|

48pc cake/plate(cake weight 32g)

|

|

|

Baking time

|

12 minutes

|

|

Baking temperature

|

185℃—210℃

|

|

Heating type

|

gas/electrical

|

Reviews

There are no reviews yet.