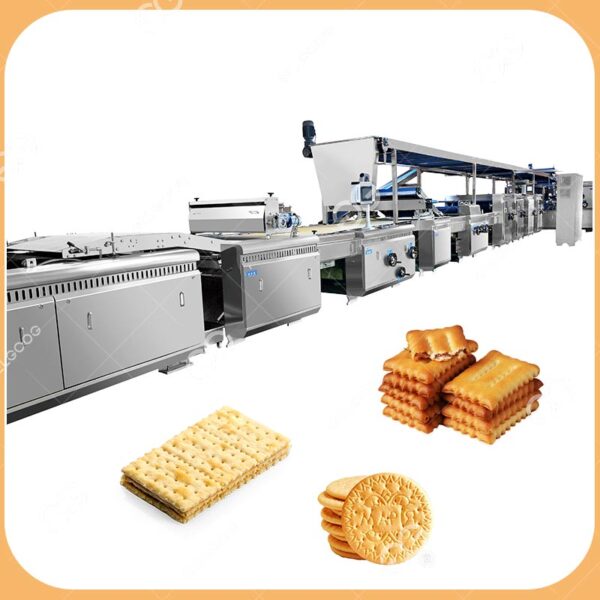

The oyster cracker production line is specilized used for large capacity oyster crackers processing. It has the advantages of high output, stable quality, and fully automated operation.

This line encompasses the entire process from dough mixing to packaging, increasing production capacity and providing crispy, flavorful oyster crackers for the snack, soup, and foodservice industries.

What Are Oyster Crackers?

Oyster crackers are small, bite-sized, slightly salty crackers, typically hexagonal in shape. They are traditionally served with soups (such as clam chowder) or enjoyed as a snack.

They have a mild, buttery flavor and a light, crisp texture, making them a versatile addition to many dishes. With growing demand in retail and foodservice, automated production ensures uniformity, hygiene, and cost-efficiency.

Features of Oyster Cracker Production Line

- 🍪 Simple Operation: Just 3 buttons to start production. Clear touchscreen with pictures (no complicated menus). Automatic warnings if something needs attention.

- 🍪 Saves Money: Uses less electricity than older machines. Makes perfect crackers every time (less waste). Can run all day without problems.

- 🍪 Easy to Clean: Smooth surfaces with no hard-to-reach spots. Comes apart quickly for washing. Special coating prevents dough from sticking.

- 🍪 Grows With Your Business: Start with basic model, add more machines later. Same workers can operate bigger systems. Easy to connect to packaging machines.

- 🍪 Always Makes Perfect Crackers: Keeps same thickness automatically. Even baking every time. Same size and shape for all crackers.

How the Production Line Works

- Dough Mixing – Ingredients are prepared according to different recipes, then thoroughly mixed to form a smooth, uniform dough.

- Sheeting & Forming – The mixed dough is then conveyed to our precision sheeting rollers, which gradually flatten it to your desired thickness. And then formed into small cracker shapes.

- Baking – The crackers are baked in a tunnel oven with different temperature zones to achieve a golden, crispy texture.

- Cooling & Packaging – The crackers are automatically cooled on the conveyor belt, bringing them to room temperature. Finally, the crackers are ready for bulk packaging.

We’re proud to offer our premium oyster cracker production line for sale to snack manufacturers across the globe. This complete system has already been successfully installed in multiple international markets, helping businesses boost their production capacity and quality.

Want to learn more about our equipment? Don’t wait, contact us now. You can reach us by email, WhatsApp, or WeChat.

- Email: lisa@machinehall.com

- WhatsApp: +8615515571373

- WeChat: gelgooglisa

Product Parameters:

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method | Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Reviews

There are no reviews yet.