The electric cake aeration system uses a high-speed impeller and aeration extrusion technology to efficiently complete the mixing and whipping of cake ingredients in a short time.

The equipment is equipped with an external feed pipe at the discharge port, which can automatically transport the whipped paste to the cake filling machine, greatly saving labor and mixing time.

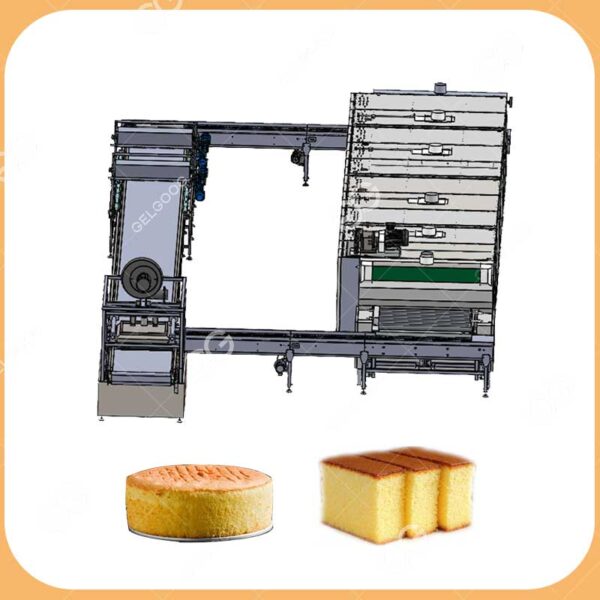

Features of Cake Aeration System

- High-efficiency whipping: The single-cylinder processing capacity is up to 40 kg, usually only 15 minutes, which significantly improves the whipping efficiency.

- Fully mixed air: The high-speed rotating agitator penetrates deep into the batter and mixes the air evenly, making the cake fluffy, dense, and rich in flavor.

- Uniform tissue density: The aerated paste has a uniform and stable tissue density, and the cakes produced have attractive color and delicate taste.

- Customized production line configuration: According to customer needs, the automatic cake aeration system can be integrated into the production line to achieve large-scale automated production.

- Intelligent control: Equipped with an intelligent control system, it can preset whipping parameters, realize automatic operation, reduce human intervention, and ensure the consistency and repeatability of each whipping.

- Compact body design: The machine is compact in design and occupies little space, suitable for kitchens or production lines of various sizes, improving space utilization efficiency.

Working Principle of Electric Cake Aeration System

- Raw material preparation: First, mix the raw materials required for the cake, such as flour, sugar, eggs, milk, oil, etc., according to the recipe ratio.

- High-speed stirring: Put the mixed raw materials into the whipping machine, and the system stirs the raw materials through the high-speed rotating impeller. During this process, the rapid rotation of the impeller generates shear force to help the raw materials mix evenly.

- Air injection: During the stirring process, the whipping system injects air into the batter evenly through specific designs, such as aeration extrusion technology. The injection of air is the key to the fluffy and soft cake.

- Bubble formation: With the injection of air, a large number of tiny bubbles are formed in the batter. These bubbles will expand during the baking process, increase the volume of the cake, and form a porous structure.

- Whipping completion: When the batter reaches the required fluffiness and consistency, the whipping process is completed. At this point, the batter has a uniform texture and a stable bubble structure.

Technical Parameter

| Capacity | 130L |

| Voltage | 380V |

| Power | 2KW |

| Weight | 650KG |

| Size | 1550*990*1500MM |

Leave Your Request for Quotation

Click to rate this post!

[Total: 0 Average: 0]

Reviews

There are no reviews yet.