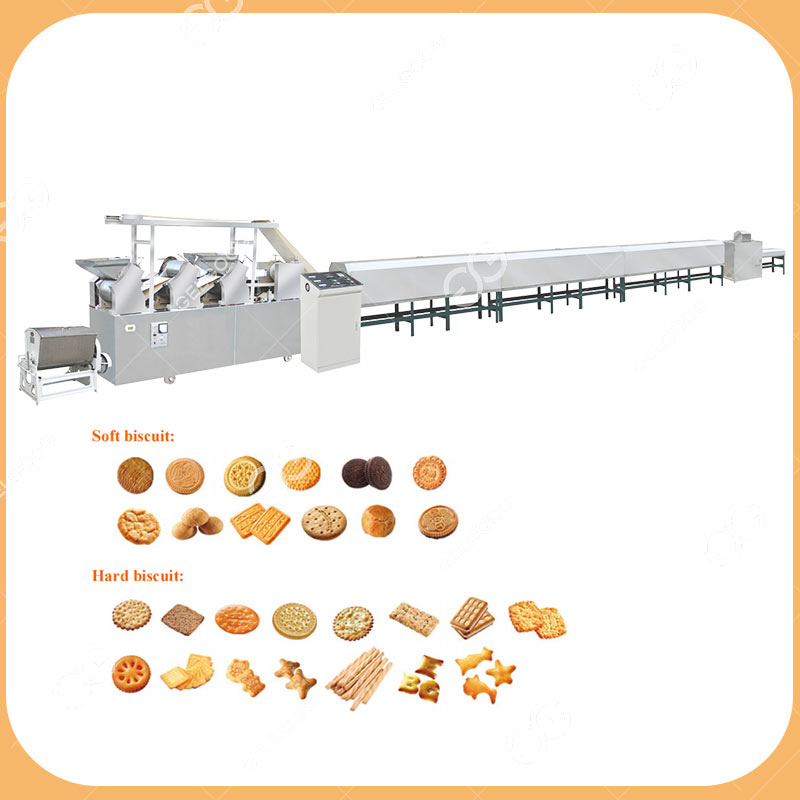

The automatic biscuit making machine is mainly consist biscuit forming machine, tunnel oven, oil spraying machine, turning machine, cooling line, biscuit arranging machine, packaging machine and so on.

This biscuit equipment can produce 300-500 kg of biscuits, besides, it can also make biscuits with a production capacity of up to 1200 kg. All depends on your needs, we can customize a plan for you.

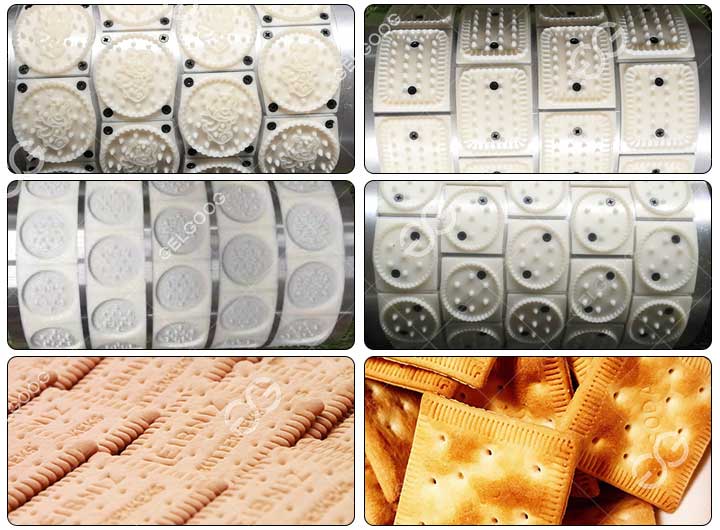

Main Molds for Biscuits

The whole industrial biscuit making machine is CPU module control, with compact structure and high degree of automation, from feeding, three pressing surfaces, forming, sugar sieving, conveying, waste, recycling. All mechatronics such as baking, oil injection and cooling are automatically completed.

Features of Automatic Biscuit Making Machine

- The whole line is controlled by CPU module, with compact structure and high degree of automation.

- Automatically complete the feeding, three-way pressing, forming (waste recycling), baking, oil spraying, cooling, conveying, and packaging processes.

- The thickness and shape of biscuits can be adjusted, and the mechanical operation speed can be adjusted steplessly.

- The biscuit baked in the tunnel oven has a moisture-repelling function, which can discharge excess moisture inside the biscuit.

- There are a series of devices such as automatic temperature control and automatic power-off alarm for leakage.

Video of Automatic Biscuit Machine

Biscuits Processing Flow:

- The processing flow of the biscuit machine is to put the mixed dough into the machine and roll it into biscuit green bodies of various shapes and sizes.

- The soft biscuit machine is to put the mixed dough into the hopper and roll it with rollers to form it at one time.

- Then bake, spray oil, and cool to produce golden and delicious biscuits, and can change the biscuit pattern according to the customer’s preference. Simple operation and low investment, it is one of the ideal equipment for investment in food processing plants.

Advantages of Automatic Biscuit Making Machine

- Save time and effort: The machine automatically completes the dough mixing, shaping, baking and packaging processes. Less labor, double the output.

- Stable taste: Computer temperature control and timing, each batch of biscuits with the exact temperature. Different styles of biscuits, adjustable temperature.

- Lower cost: Accurate delivery of raw materials without waste, 24-hour non-stop production, each biscuit is more economical.

- Clean and hygienic: From the flour entering the industrial biscuit processing machine to the packaging and sealing, no hands touch the food throughout the process, which is very clean and hygienic.

- Variety of styles: You can make different shapes by changing the mold, and you can make sandwich biscuits by adding a sandwich machine, and launch new styles are very quickly.

Product Parameters:

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method | Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Leave Your Request for Quotation

Click to rate this post!

[Total: 0 Average: 0]

Reviews

There are no reviews yet.