The specialized equipment for Swiss roll cakes is suitable for industrial scale, these machines are essential to ensure efficiency, consistency, and quality in the manufacturing process.

Swiss roll cakes are a classic sponge cake delicately rolled with fillings such as whipped cream, jam. In order to produce in bulk while maintaining quality standards, equipment is essential. Here are some of the key industrial equipment needed to produce Swiss cake rolls:

- Mixing and Blending Equipment: This machine is used to mix the batter ingredients thoroughly and consistently. The machines can handle large batches of batter, ensuring uniformity in texture and flavor.

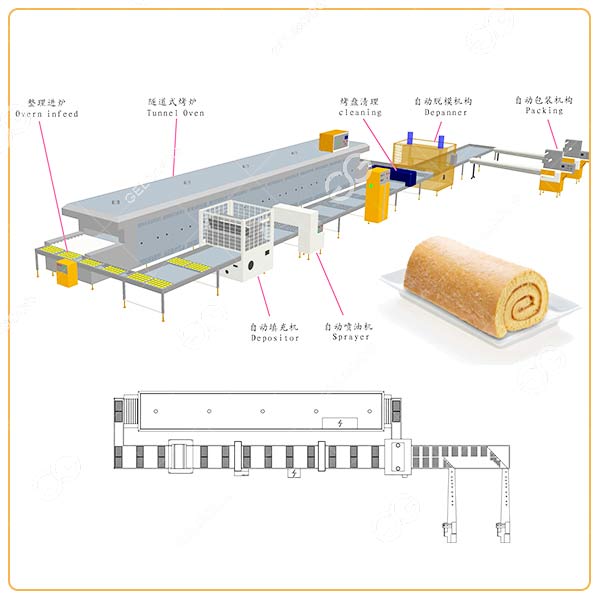

- Automatic Batter Depositor: It is used to accurately portion out the Swiss roll cakes batter onto baking trays or sheets. The machine ensure consistent portion sizes and distribution of batter, which is crucial for uniform cake layers.

- Continuous Baking Oven: This oven designed to bake large quantities of cake layers quickly and efficiently. The oven has conveyor belts that move the cake trays through the baking chamber, ensuring even baking and consistent quality across all cake layers.

- Cooling Conveyor: After baking, cake layers need to be cooled rapidly to prevent overcooking and ensure proper texture. Cooling conveyor is used to transport the hot cake layers from the oven to the cooling area, where they are cooled down to room temperature before further processing.

- Filling and Spreading Machine: This machine is used to automate the process of applying filling onto the cake layers. It ensure precise and consistent application of fillings such as cream, jam, or frosting, saving time and labor costs.

- Rolling and Cutting Machine: Swiss roll cakes require precise rolling and cutting to achieve the desired spiral shape and portion sizes. Industrial rolling and cutting machines are used to automate these processes, ensuring uniformity and efficiency in production.

- Packaging Equipment: Once the Swiss roll cakes are rolled, filled, and cut, they need to be packaged for distribution and sale. Packaging equipment such as flow wrappers or vertical form-fill-seal machines are used to wrap the cakes securely in packaging material, preserving freshness and extending shelf life.

- Labeling system: It is an integral part of industrial Swiss roll cakes production lines. These systems play a crucial role in applying product labels, expiration dates, and other essential information to the packaging. By doing so, they ensure compliance with regulatory requirements while also providing consumers with important product details.

- Cleaning and Sanitizing Equipment: Maintaining cleanliness and sanitation in a food production facility is essential for ensuring product safety and quality. Industrial cleaning and sanitizing equipment, such as conveyor belt cleaners, foamers, and sanitizing tunnels, are used to effectively clean and sanitize equipment and surfaces to prevent contamination.

By using these equipment for Swiss roll cakes production, manufacturers can streamline operations, increase productivity, and deliver high-quality products to meet consumer demand. If you want to start this business, please contact us.