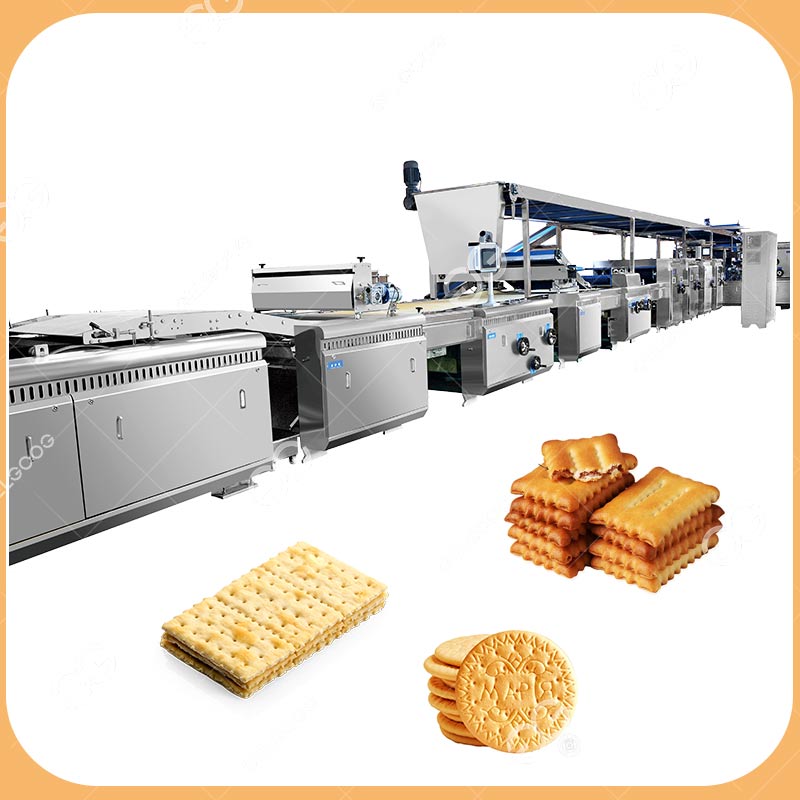

The hard biscuit production line is suitable for producing hard biscuits on a large scale and improve the production capacity of biscuit manufacturers. It not only has professional machinery and technology, but also professional services.

These services include production line quotation, design proposals, factory layout planning, recipe provision, and factory trial runs. This allows you to truly experience our company’s professionalism and the performance of our equipment.

Main Equipment of Hard Biscuit Production Line

★Dough Mixing Machine: This machine proportionally blends ingredients like flour, sugar, oil, leavening agents, and flavors to form a uniform dough.

★Dough Sheeter Machine: The dough passes through several rolling stages to reach the desired thickness for hard biscuits, typically around 0.8 mm and as thin as 0.6 mm when required.

★Hard Biscuit Forming Machine: The dough sheet is shaped into uniform hard biscuits through roller cutting, with the trimmed dough collected and reused to reduce material waste.

★Biscuit Baking Oven: Within this large tunnel oven, hard biscuits are conveyed through four key stages—expansion, shaping, dehydration, and coloring—to achieve a consistently baked texture.

★Cooling and Sterilization Line: This conveyor belt cools the baked biscuits to prevent moisture retention, preserving their crispness and preparing them for packaging.

★Packaging Machine: The cooled biscuits are then packed into boxes, bags, or other containers by this machine, extending shelf life and preparing them for distribution.

Video of Hard Dough Biscuit Production Line

Multifunction of Complete Hard Biscuit Solution

This line offers a variety of mold options, allowing biscuit manufacturers to produce a wide variety of hard biscuit types and styles using a single set of equipment. Simply changing the forming mold or adjusting production parameters allows for customized shapes and styles.

This versatility and customization help food manufacturers reduce equipment investment, optimize production space, and meet diverse market demands. The following are examples of some common hard biscuit forming molds.

Features of Automatic Hard Biscuit Production Line

Product Parameters:

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method | Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Reviews

There are no reviews yet.