How is cake made in a factory? It’s a highly automated, precisely controlled process. It allows food manufacturers to achieve large-scale cake production.

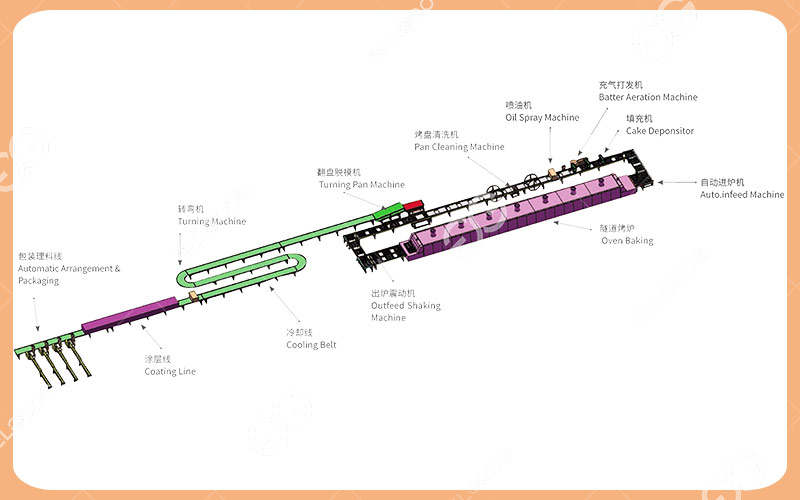

This article shows the main steps of making cakes in factory. The entire process can be clearly divided into the following core steps:

Step 1: Ingredient Scaling and Pre-Mixing

The process begins with the automated scaling of ingredients. Bulk quantities of flour, sugar, and other dry components are stored in large silos and are precisely weighed and transported via pneumatic systems to giant mixing stations. Liquids like water, milk, oils, and liquid eggs are similarly pumped in through meters that ensure exact volumes. This stage is critical for consistency, answering the first part of how is cake made in a factory with an emphasis on accuracy and repeatability.

Step 2: Industrial Mixing

The pre-measured ingredients are then combined in massive, high-speed mixers. These industrial machines are designed to handle hundreds of kilograms of batter at a time, using specific techniques (like creaming or all-in-one) to develop the perfect airy texture. Any additions, such as chocolate chips or flavourings, are automatically folded in at precisely the right moment. The mixed batter is then pumped through hygienic pipes directly to the next stage.

Step 3: Depositing and Panning

The batter is no longer handled by hand. Instead, it is automatically deposited by filling heads into waiting pans or directly onto a continuous conveyor belt. These depositors are incredibly accurate, ensuring each cake or cupcake has the exact same weight and shape, which is a cornerstone of the industrial cake manufacturing process.

Step 4: Tunnel Baking

The filled pans or trays enter a multi-zone tunnel oven on a long, slow-moving conveyor belt. Each zone of the oven has a different, carefully controlled temperature, allowing the cakes to bake perfectly from the outside in without burning. The baking time is determined solely by the speed of the conveyor.

Step 5: Controlled Cooling

After exiting the oven, the baked cakes must be cooled evenly and completely before any frosting can be applied. They travel on a conveyor through a long, chilled cooling tunnel or a special cooling room. This step is vital to stabilize the cake’s structure and prevent condensation inside the packaging.

Step 6: Icing, Decorating, and Assembly

For layered cakes, machines automatically slice them, add filling, and reassemble them. Icing is applied by spinning heads for cupcakes or by a flowing curtain of glaze for sheet cakes. Sprinkles and other decorations are added by automated depositors. This stage showcases the robotic precision of how mass-produced cake is created.

Step 7: Automated Packaging and Quality Control

The final step is automated packaging. Machines swiftly wrap individual cakes or place them into plastic clamshell containers. This seals in freshness and protects the product. Throughout this entire factory cake production line, quality control checks are constantly performed to ensure every cake meets strict standards for weight, appearance, and safety before being shipped to stores.

Making cakes in a factory is a breakthrough in transforming traditional baking techniques into a sophisticated industrial process. Through automation and intelligent technology, we achieve efficiency, scale, and quality.